Application Background of Laser Particle Counters in Lithium - Ion Battery Manufacturing Industry

In the lithium - ion battery manufacturing industry, the safety, energy density, and cycle life of batteries are core indicators. However, dust particles in the production environment are key hidden dangers that threaten these indicators. With the development of lithium - ion batteries towards higher capacity and higher integration, the requirements for environmental cleanliness have become increasingly strict. From the mixing of positive electrode materials and the coating of negative electrodes to the winding / lamination of battery cells and the liquid injection and packaging, every link must be strictly guarded against dust intrusion. If micron - level dust is mixed into the positive electrode slurry, it will reduce the uniformity of the electrode coating and affect the charge - discharge efficiency of the battery. If dust adheres to the surface of the battery cell separator, it may pierce the separator and cause a short circuit between the positive and negative electrodes, which in turn leads to battery bulging, fire, or even explosion. Even extremely small metal dust may form micro - current channels inside the battery, significantly shortening the cycle life and bringing safety risks to end - use applications such as new energy vehicles and energy storage equipment.

Hardware Equipment

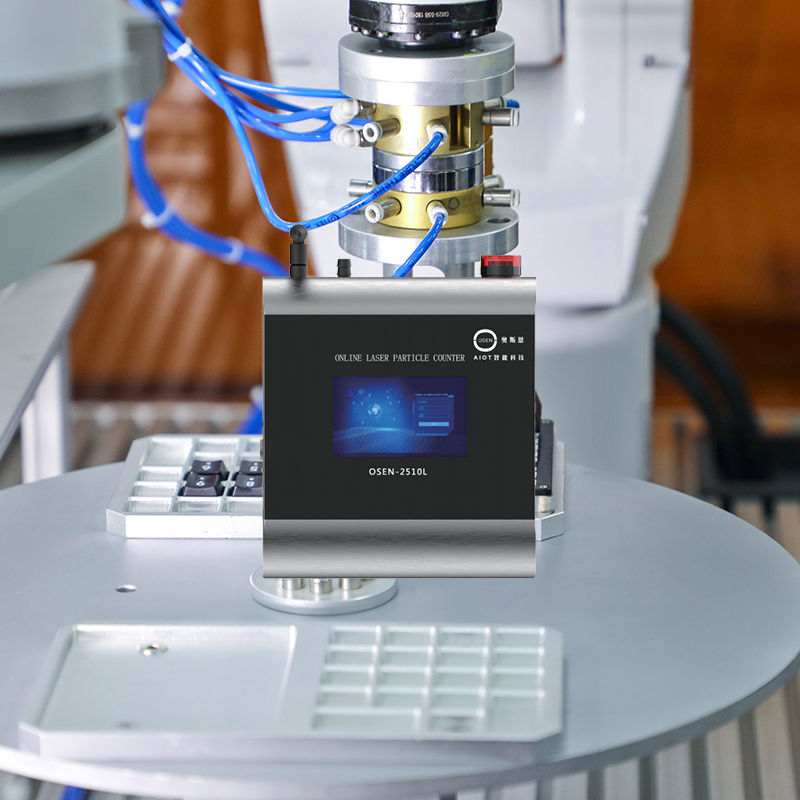

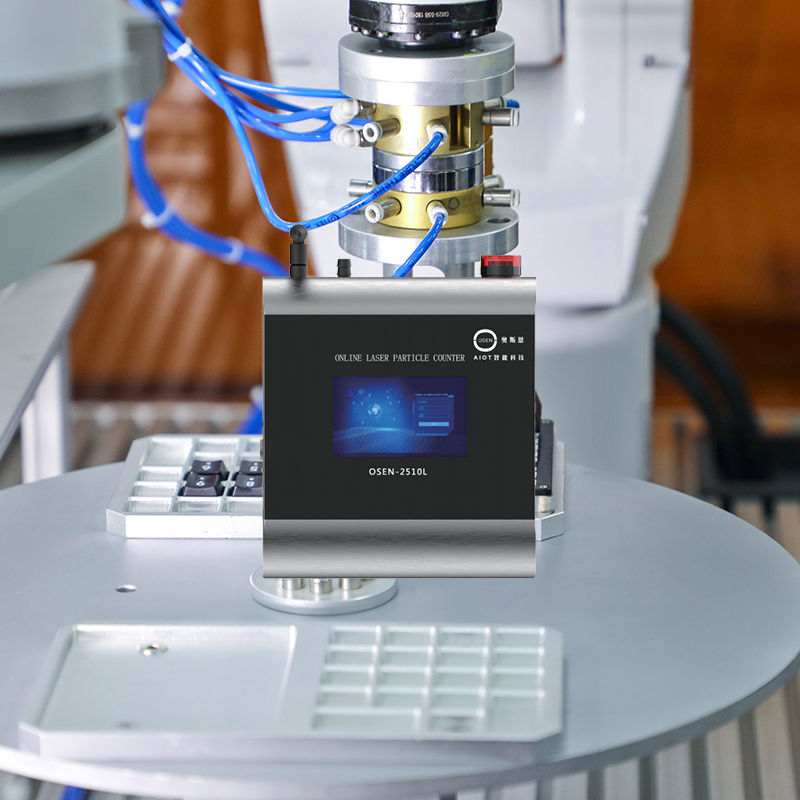

OSEN - 2510L Type 0.1μm Online Laser Particle Counter

The OSEN - 2510L Type 0.1μm Laser Particle Counter is a new - generation product independently developed by our company. Based on the principle of light scattering, the counter realizes the detection of the particle size of dust particles and the counting of the number of particles through photoelectric sensing technology. Compared with ordinary large - flow particle counters, this instrument has a smaller detection particle size, which can detect particles as small as 0.1μm. It is suitable for class 1 to class 10 ultra - clean environments and applicable to ultra - clean scenarios such as electronics, semiconductors, liquid crystal panels, micro - nano processing, aerospace, precision processing, new materials, and scientific research institutions.

Technical Parameters

Particle Size Range: 0.1μm - 10.0μm

Standard Particle Size Channels: 0.1μm, 0.2μm, 0.3μm, 0.5μm

Counting Efficiency for 0.1μm Particle Size: 50 ± 20%

Concentration Indication Error: ± 20% FS for 0.5μm particles

Maximum Sampling Concentration: 500,000 PC/CFM. It has concentration over - limit protection and prompts the instrument to self - clean.

Repeatability Error: 5% F.S

Self - Cleaning Time: ≤ 10min

Sampling Flow Rate: 28.3L ± 5%. It has real - time monitoring and over - limit alarm functions.

Sampling Cycle: 1 - 9999s (configurable)

Continuous Operation: Supports 24 - hour non - stop stable operation

Laser Light Source: Long - life imported semiconductor laser diode from Japan

Vacuum: Internal vacuum source with a service life of > 20,000 hours

Display: 4.3 - inch touch screen

Power Supply: DC24V/1A

Communication Methods: RS485 @ ModbusRTU / Ethernet @ ModbusTCP / Wireless Communication @ LoRa

Calibration Standards: JF1190 - 2008, GB/T 25915.1 - 2021

Housing: 304 stainless steel

Dimensions: Width 19.2cm * Depth 21.2cm * Height 15.2cm

Weight: 4kg

Operating Environment Temperature: 0 - 40℃, Relative Humidity 10% - 90% (non - condensing)

Storage Environment: Temperature - 10 - 50℃, Relative Humidity 0 - 90% (non - condensing)

Keyword: