The online monitoring solution for clean environments provides a sampling flow rate of up to 50 liters per minute

2025-06-03 00:30:38

Development background of online monitoring of clean environment

Modern cleanrooms originated from the military industry during wartime. During the Korean War in the 1950s, the United States discovered that a large number of electronic instruments had malfunctioned during the war, with over 80% of radars failing, nearly 50% of underwater acoustic locators failing, 70% of electronic equipment in the army failing, and annual maintenance costs exceeding twice the original price due to poor reliability and unstable quality of components. In the end, the main reason found by the US military was that dust was causing trouble and the factory production environment was not clean, resulting in a low pass rate of the produced parts. Although very strict measures were taken to close the production workshop at that time, the effect was still minimal. Later, high-efficiency air filters were applied to the production workshop to solve such problems, which is also the birth of modern clean rooms.

The indoor production environment is an important factor affecting product quality. In the electronics industry, the pollution of suspended particles in the production process can reduce quality or even scrap, resulting in a low product qualification rate; In the pharmaceutical and food industries, the presence of microorganisms can directly reduce product qualification rates, lower product quality, and shorten shelf life.

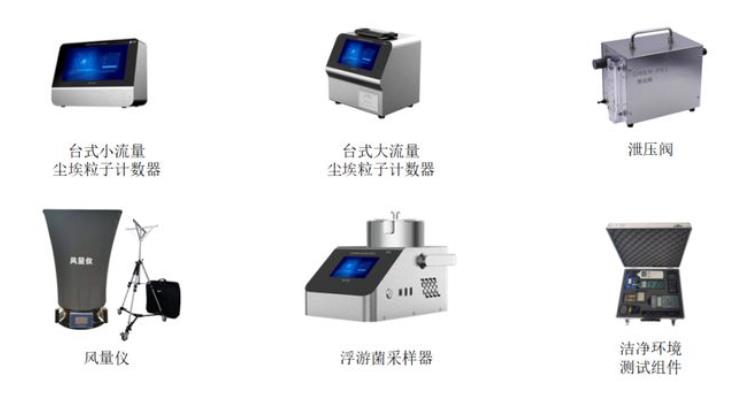

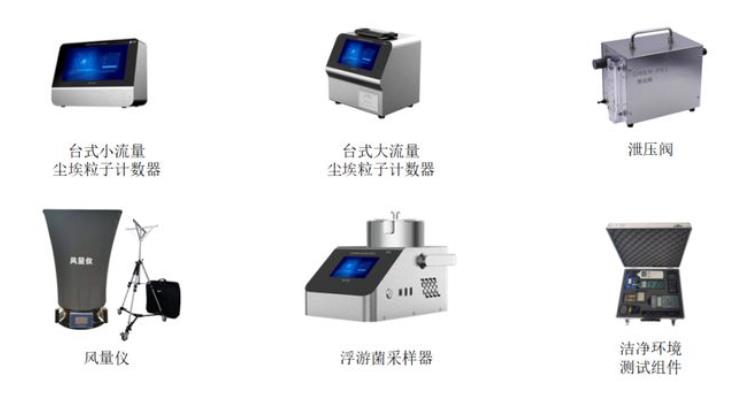

Hardware equipment for online monitoring of clean environment

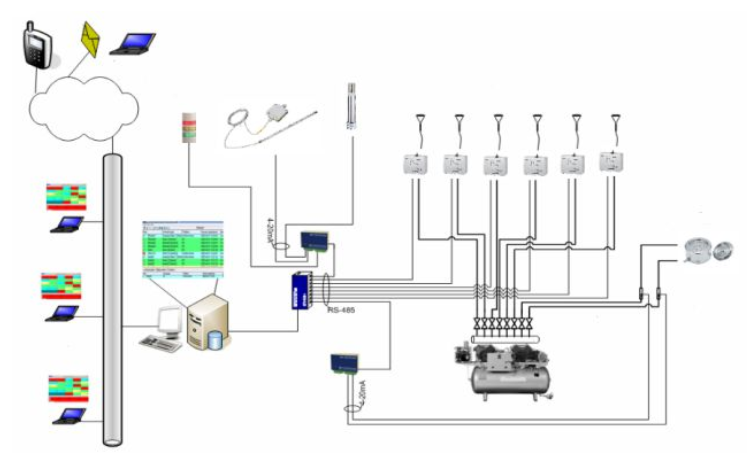

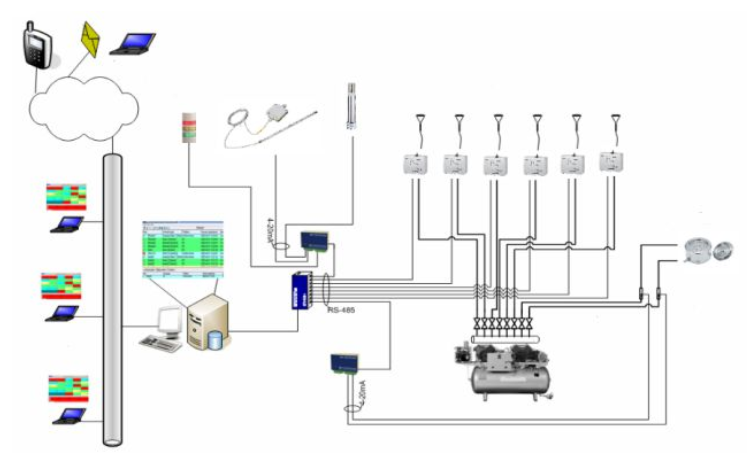

Product topology diagram

Cleanroom Environment Series Products

Online Particle Monitoring System

This system and its customized services can meet users´ requirements for continuous online particle monitoring in the production areas of cleanrooms. All sampling points in the cleanroom simultaneously monitor particle conditions of 0.5μm and 5.0μm, complying with relevant regulations of GB50073-2013, ISO14644, GB/T16292-2010, US FDA, EU GMP, and China´s current cGMP.

Featured Features

1) Remote control function: It can be remotely monitored and set alarms, data storage, report editing, printing and output in real-time through a computer in the control room.

2) Particle monitoring function: Use the OSEN-5016M/5104M particle counter (0.5, 5.0 microns 2.83/28.3 liters/minute) to monitor the number of particles in the air.

3) Flow monitoring function: Monitor the operating flow of each particle monitoring device and provide the status of whether the flow is running normally, such as providing alarm feedback when the set point flow rate is ± 5%, and realizing real-time self-regulation of the flow rate.

4) Continuous monitoring function: The particle counter working in a clean environment can perform continuous monitoring work 24 hours a day and has built-in flow monitoring.

5) Floating bacteria sampling function: The provided sampling flow rate can reach 50 liters/minute, achieving non interfering sampling in the sterile filling area and an external sampling tray action plan.

6) Sound and light alarm function: The alarm system has multiple alarm functions such as sampling flow alarm, communication failure alarm, numerical exceeding alarm, hardware fault alarm, etc. It provides alarm reminders through sound, light and other means to ensure the long-term safe and stable operation of the system;

7) Expand the monitoring function of other parameters such as wind speed, temperature and humidity, and pressure difference: monitor real-time wind speed, temperature and humidity, and pressure difference data of the arranged points;

8) On site display function: The production site is equipped with an operation screen or display screen to operate or display the monitoring data of the on-site room, making the operation more convenient and the display more intuitive, thereby improving organizational efficiency.

Keyword: