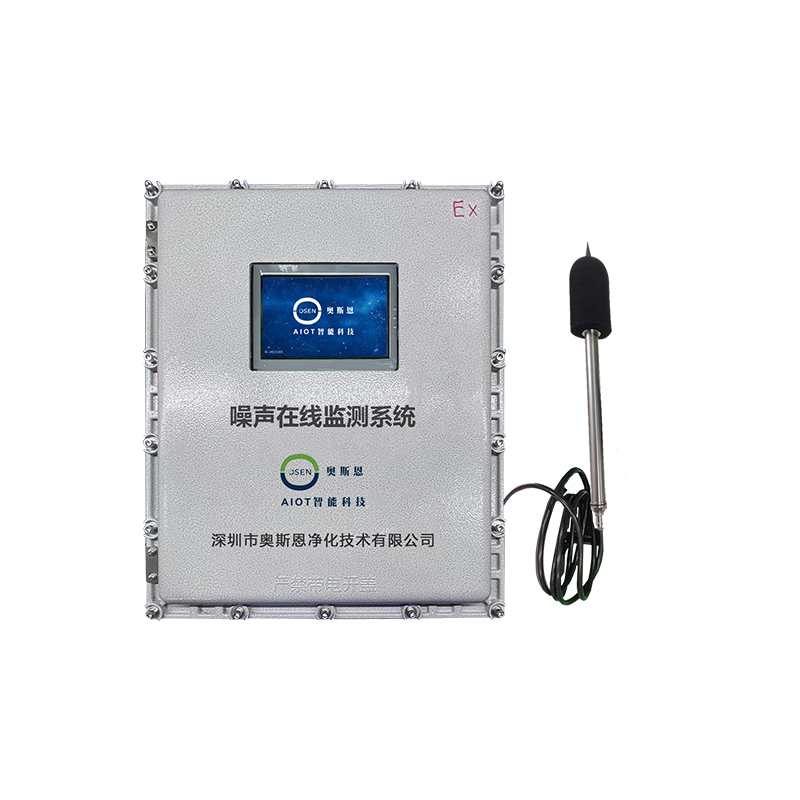

Solution for Explosion proof Noise Monitoring System in Aerospace Industry

2025-06-23 08:23:30

In industrial production environments, noise not only affects the physical and mental health of employees, but may also become a "warning signal" for safety hazards. Especially in some flammable and explosive special places, the importance of noise monitoring is self-evident. The Osen explosion-proof noise monitoring system has become a powerful assistant in the field of industrial noise monitoring.

The explosion-proof noise monitoring system meets the requirements of GB/T3785.1 for Level 1 sound level meters, and the equipment has functions including automatic calibration of microphones, recording, and frequency spectrum analysis of 1/1 octave and 1/3 octave bands; Meet the requirements of GB3096-2008 "Quality of Acoustic Environment", HJ906-2017 "Technical Specification for Automatic Monitoring of Acoustic Environment Quality in Functional Areas", and HJ907-2017 "Technical Requirements for Automatic Monitoring System of Environmental Noise" for automatic monitoring of noise in functional areas.

The explosion-proof noise monitoring system mainly consists of a noise monitoring substation (all-weather outdoor microphone, noise acquisition and analysis unit, communication unit, power supply system, meteorological monitoring module, etc.), a central server, and an automatic monitoring data statistical analysis platform for sound environment. It can monitor and analyze the characteristics of environmental noise, determine the source of noise, and achieve remote data telemetry, noise event monitoring, system automatic calibration through wireless or wired network transmission, ultimately forming multiple reports.

Functional Features

1. High integration and flexible solution: the system can expand sound source tracking, sound source capture, voiceprint recognition, pedestrian flow, vehicle flow, and video surveillance;

2. Equipped with a wind cover, which can be used to reduce the impact of wind noise when measuring in windy environments;

3. Integrated data collection, transmission, and publishing display. By integrating high and flexible solutions and modular deployment, it can meet the needs of different occasions;

4. No tool disassembly, convenient for point migration and equipment maintenance;

5. Multimedia display: can be equipped with monochrome, dual color, tri color, full-color, customizable display interface, and additional display time and date information;

6. Excessive recording: If the noise data exceeds the standard, the camera recording function should be triggered in a timely manner;

7.24-hour automatic monitoring, no need for manual intervention, stable and reliable;

8. Noise exceeding alarm can be triggered by setting alarm conditions;

9. Able to provide custom reports and generate required reports according to user requirements.

10. Combining PC cloud platform and mobile applications to view real-time data, statistical curves, noise pollution trend prediction and other information anytime and anywhere, effectively controlling noise pollution.

Featured Features

voiceprint recognition

Classify the noise in the environment to determine its possible sources and types. The sound types are mainly divided into five categories: domestic noise, construction noise, industrial noise, traffic noise, and natural noise, including no less than 50 subcategories such as thunder, wind, knocking, insect and bird sounds.

Sound source tracking

The sound source tracking and positioning radar is equipped with noise source positioning function. Through precise positioning and microphone phase matching algorithms, it intuitively displays the direction of the sound source, reports excessive alarms and captures videos (with surveillance cameras), and has on-site recording evidence storage and recording function.

Excessive recording

Configure the recorder to automatically trigger the recording function when the noise data exceeds the standard, and upload audio traces, supporting playback and playback.

Constant temperature heating device

To adapt to the ultra-low temperature climate environment in the north, the equipment is equipped with a constant temperature heating device. A constant temperature heating device is installed on the equipment. When the ambient temperature is lower than the set temperature of the device, it automatically starts heating to maintain a constant temperature, avoiding the equipment from being affected by too low a temperature.

Interrupted network and continued transmission

To prevent the occurrence of network disconnection in equipment, which may lead to the loss of monitoring data, our company has developed a breakpoint resume function. When the equipment detects a network interruption, it automatically saves the monitoring data locally. After detecting that the equipment has recovered from the network, the data monitored during the disconnection period is automatically uploaded to the server for storage.

Over limit alarm

The device can set an alarm threshold and support remote setting. When the noise data exceeds this value, the device will automatically sound an alarm and upload it to the supervision platform. Supervisors will be reminded through the PC platform or mobile WeChat platform. If the device is equipped with an alarm, it can automatically link with the alarm for sound and light alarm

Remote calibration

Equipped with remote automatic calibration function, the electrostatic exciter can be activated by sending an ACT command remotely. By default, the electrostatic exciter generates a sound pressure level of 94dB to remotely calibrate the microphone and ensure data accuracy.

Keyword: